EN 388: The safety glove standard explained

What are EN standards?

EN standards are a set of technical classifications created by the European Committee for Standardization (CEN) designed to ensure that certain products and services, including various PPE products like safety gloves, are graded towards or meet certain sets of standards.

EN standards are crucial to many types of PPE products like safety gloves to ensure that they are fit for their required purpose.

What is EN 388?

EN 388 is the technical classification to evaluate the performance of safety gloves against particular types of hazard. Safety gloves are put through several tests to determine how they perform. The test includes common hazards such as performance against abrasion, cutting, tearing, puncturing, and impact. As of 2016 tests against cuts are performed in two different methods, which we’ll cover later. Each test will give the glove a grading, which is sometimes referred to as a “mechanical rating”.

How to identify if a glove has an EN 388 rating

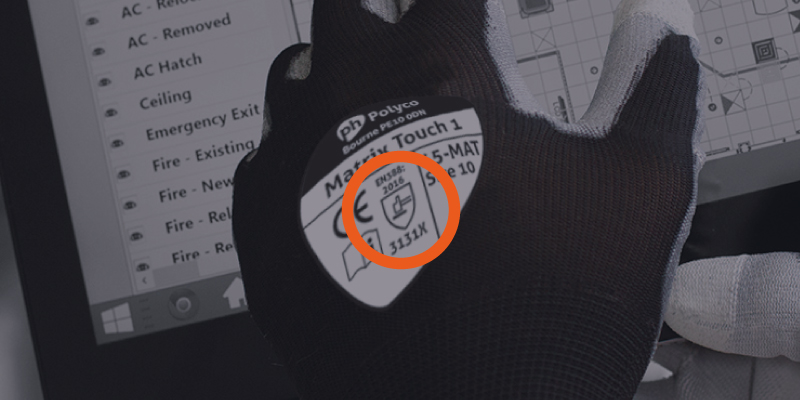

To identify the EN 388 grading of a safety glove, it is usually printed directly onto the garment with a pictogram and a series of numbers and letters, most often in the position on the back of the hand, however sometimes it may be displayed within an internal label.

If no EN 388 standard is prevalent on your pair of safety gloves, be sure to check with the supplier or manufacturer if it has been tested to EN 388 and check with your health and safety officer that they are suitable for the task you are undertaking.

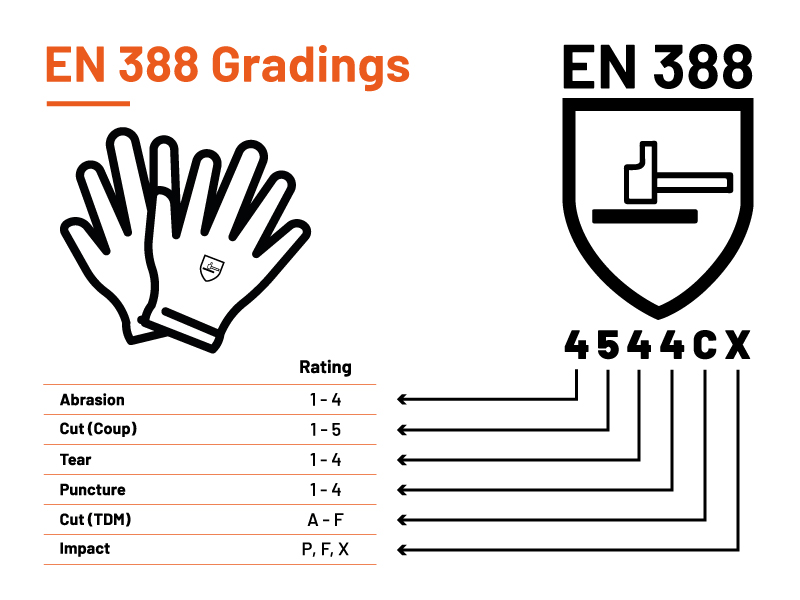

What do the EN 388 numbers and letters mean?

When a safety glove conforms to EN 388, it's grading (or “mechanical rating”) is generally reported along with “EN 388” in written form as a sequence of numbers and letters, each number and letter represents how well the glove faired against each test.

What are the EN 388 testing methods?

For gloves tested after the updated standard in 2016, the order of the reported grading is always as follows:

Abrasion

Rating: 1 (Low) – 4 (High)

The safety glove material is exposed to abrasion by sandpaper under a set pressure. The grading is based on the quantity of turns the material is subjected to until a hole is formed, breaking the integrity of the glove. The higher the grading value is, the better its protection against abrasiveness is.

| Turns | Rating |

| 8000 | 4 |

| 2000 | 3 |

| 500 | 2 |

| 100 | 1 |

| < 100 | 0 |

Cut (Coup Test)

Rating: 1 (Low) – 5 (High)

The safety glove material is subjected to a cutting action from a rotating circular blade backwards and forwards with a 5 newton level of force. Once the blade has successfully broken through the material of the glove, the test is complete and the glove is graded based on the count of blade rotations that the material as well as the bluntness of the blade.

If the material successfully blunts the blade, the glove material qualifies for the next level of more advanced cut testing (TDM).

| Factor | Rating |

| 20 | 5 |

| 10 | 4 |

| 5 | 3 |

| 2.5 | 2 |

| 1.2 | 1 |

| < 1.2 | 0 |

Tear

Rating: 1 (Low) – 4 (High)

The safety glove material is positioned between two clamps which together pull the material apart. This determines how much force can be applied to the material before it tears apart, once the material has completely split, the test is complete and a grading is given based on the force in newtons the material resisted until snapping.

| Newtons | Rating |

| 75 | 4 |

| 50 | 3 |

| 25 | 2 |

| 10 | 1 |

| < 10 | 0 |

Puncture

Rating: 1 (Low) – 4 (High)

The safety glove material is positioned under a rounded point and pushed through the material at a set speed. The force required to pierce the material is the measure in which it’s graded to puncture resistance.

| Newtons | Rating |

| 150 | 4 |

| 100 | 3 |

| 60 | 2 |

| 20 | 1 |

| < 20 | 0 |

Cut (TDM)

Rating: A (Low) – F (High)

This method of testing was introduced in 2016 as part of the updated standard in accordance with EN ISO 13997. As specified in the previous cut test (coup), some gloves may qualify for the next level of cut test (TDM) whereby the material is subjected to a significant force in a single movement instead of a circular cutting motion.

A straight blade cuts the material at a consistent speed but with increasing force, this is designed to replicate cutting hazards at high impact. The grading for this test is no longer numbers, but letters with A being low and F being high, in alphabetical order. The greater the force the material withstands without ripping, the higher grade it will receive.

| Newtons | Rating |

| ≥ 30 | F |

| ≥ 22 | E |

| ≥ 15 | D |

| ≥ 10 | C |

| ≥ 5 | B |

| ≥ 2 | A |

Impact

Rating: P (Pass), F (Fail)

Another method of testing introduced in 2016, the impact test involves the safety glove being subjected to a force of impact from a striking machine with a 2.5kg weight. If the glove appears to absorb the impact from 7kN force, it passes the test.

| Level kN | Rating |

| ≥ 7kN | P (Pass) |

| < 7kN | F (Fail) |

If any of the characters display an “X” instead of a grading value, this means that the test has either failed, hasn’t been performed, or isn’t applicable to that particular type of safety glove. If any of the first four gradings displays as a “0” instead, this means that the minimum level 1 hasn’t been achieved.

Safety gloves tested before 2016 may only have the first four of these gradings, as the additional cut (TDM) test and impact test were added post update.

Bigger isn’t always better

High ratings don’t always mean that a glove is “better” for the task you’re undertaking. Generally speaking, some gloves may grade highly across the board for the EN 388 testing, however, they could be a thicker material which may be unsuitable for tasks that require high levels of dexterity.

Another key example of this principle in practice is for wearers that operate certain types of machinery where a low tear resistance could be better; if the glove gets caught or snagged in the machinery, there is an increased chance that the glove tearing away from the wearer's hand will reduce their chance of injury.

So be careful to not assume that “the bigger the grading the better the glove”, it entirely depends on what task is being undertaken.